Dome Solar, a specialist in photovoltaic mounting for large roofs, stands out from other photovoltaic installers due to its innovative heat-welded systems for flat roofs.

The advantage of these systems is that they allow photovoltaic panels to be mounted on flat roofs without ballasting.

There are two heat-welding systems depending on the type of membrane:

- Bitumen membrane by flame welding.

- Synthetic membranes (PVC and TPO) by hot air welding.

Each of them requires the intervention of a professional weatherproofer.

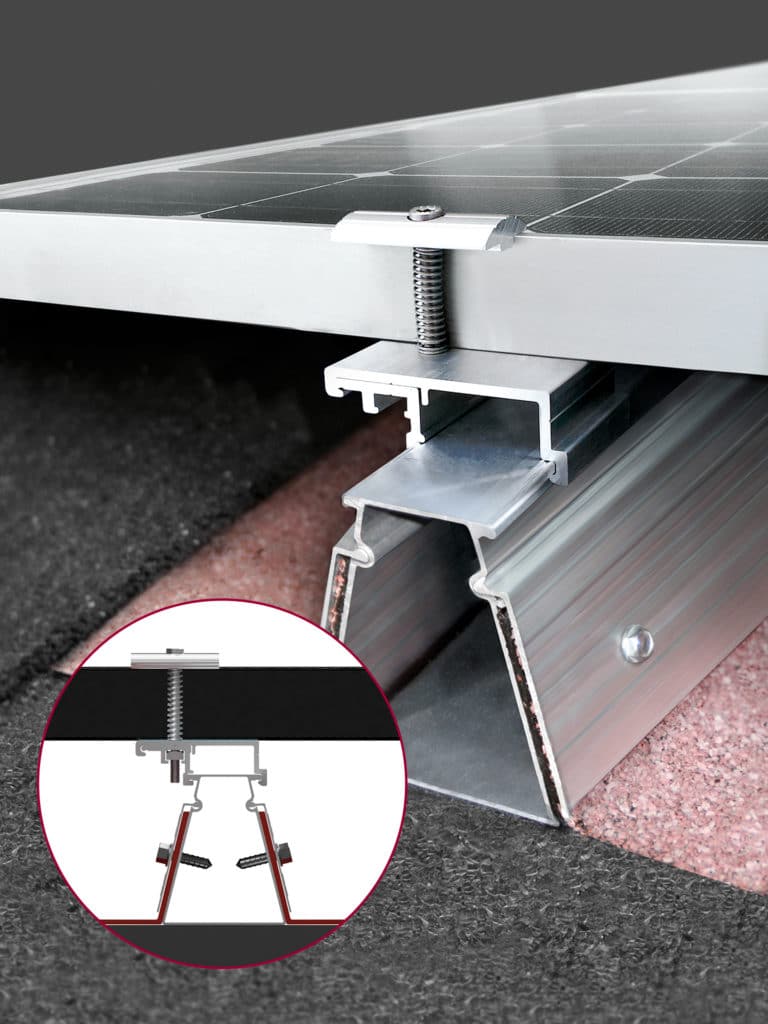

For a bitumen flat roof

The system is comprised of a set of rails: 1 rail and 2 retaining strips that are pre-mounted on the rail using 2 flanges.

The 4 installation steps are:

- Grid marked on the roof using a string or a laser based on the plans provided by Dome Solar;

- Marking in crayon of the precise location of the rails;

- The shiny surface of the membrane is heated so that the slate flakes melt down and penetrate into the bitumen;

- Positioning of the rail and flame welding of the two retaining strips.

These 4 steps are a mandatory protocol for the correct installation of Roof-Solar Bitumen and Roof-Solar Tilted Bitumen systems.

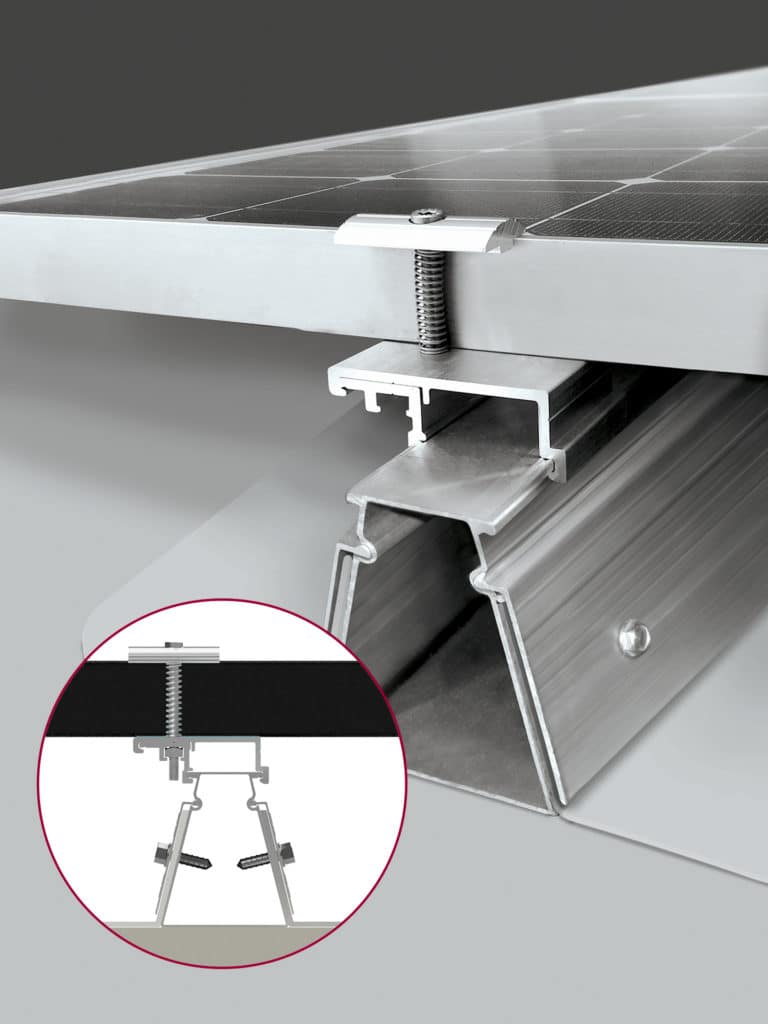

For a PVC or TPO synthetic flat roof

The set of rails is hot air welded.

The 4 installation steps are:

- Grid marked on the roof using a string or a laser based on the plans provided by Dome Solar;

- Marking in crayon of the precise location of the rails;

- Positioning of the rail and hot air welding of the two retaining strips;

- Tack welding of reinforcing patches in the corner of the rails.

These 4 steps are a mandatory protocol for the correct installation of Roof-Solar PVC, Roof-Solar Tilted PVC, Roof-Solar TPO and Roof-Solar Tilted TPO mounting systems.

This technique, which does not require any ballasting, has the advantage of limiting the weight to be borne by your roof.