ROOF-SOLAR TILTED PVC

Mounting for photovoltaic panels thermally welded to a synthetic membrane

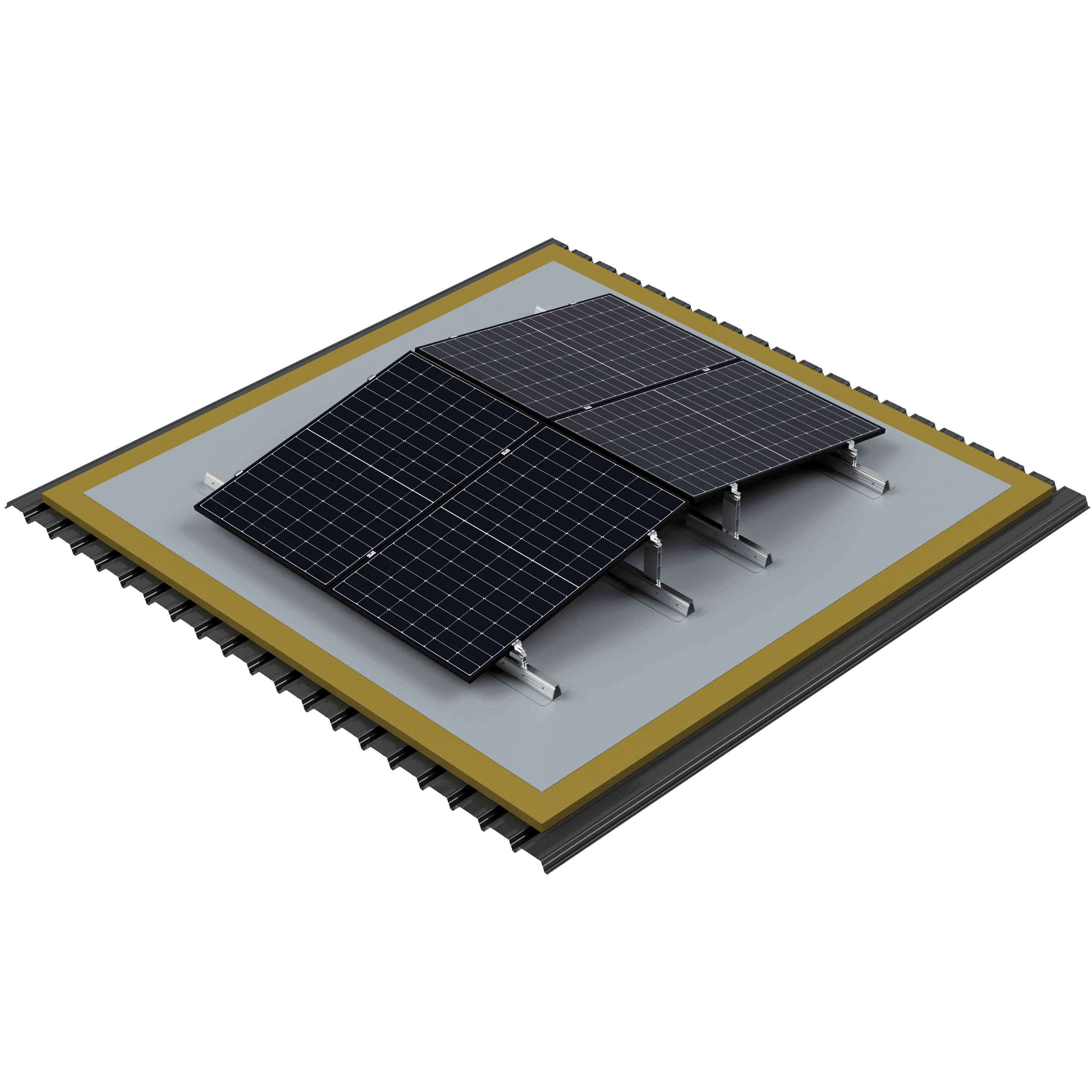

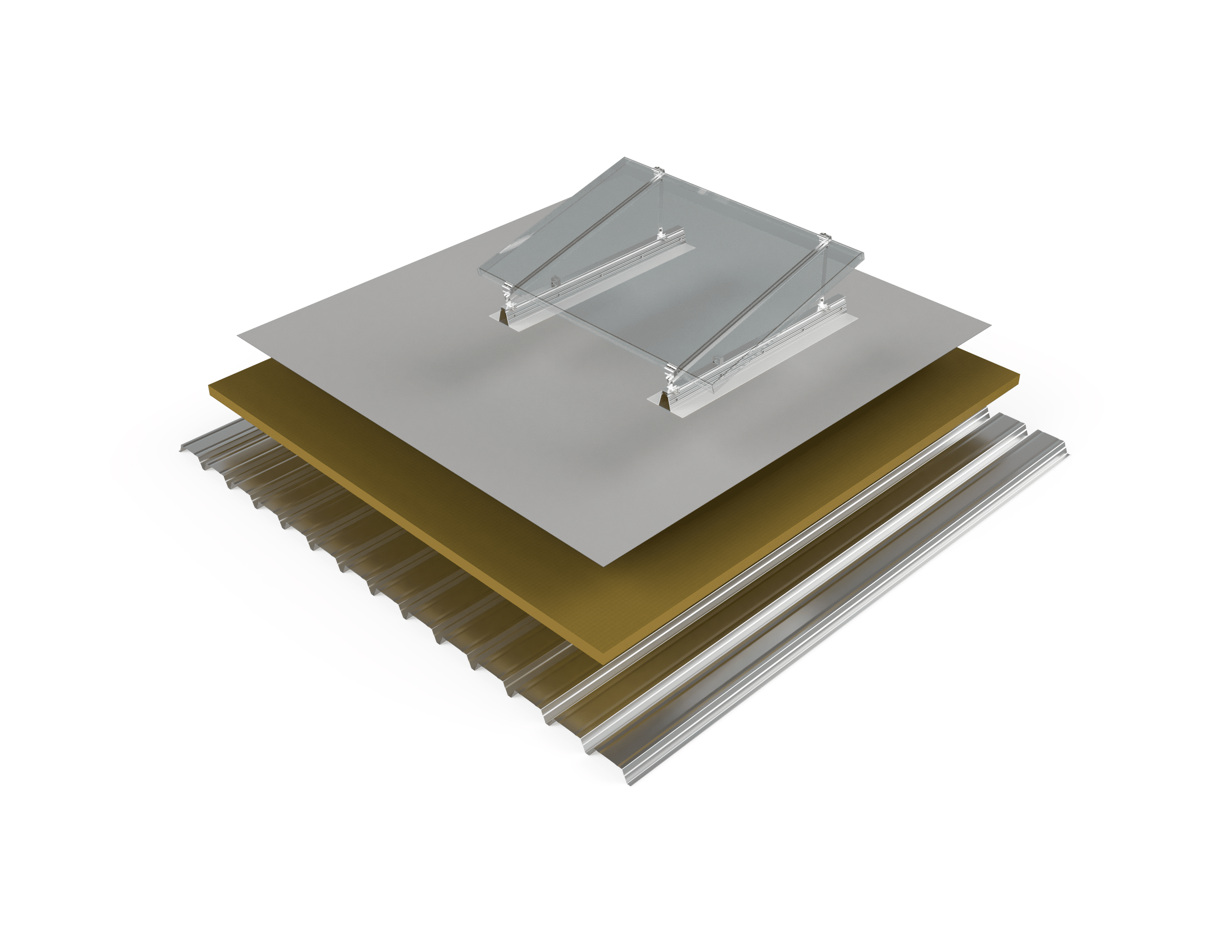

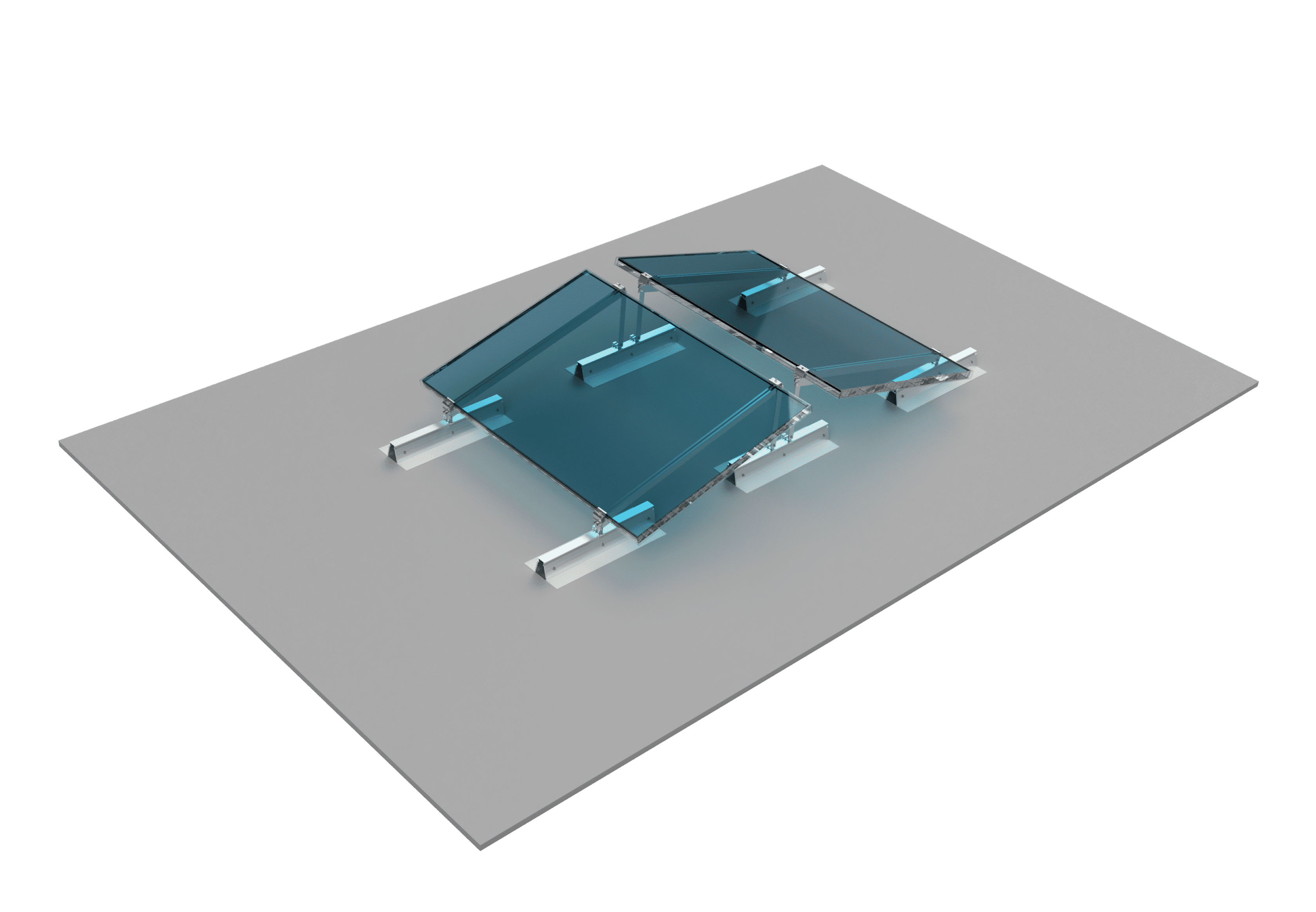

Roof-Solar Tilted PVC is a photovoltaic mounting system used for installing solar panels on flat roofs. It is used on buildings with synthetic PVC membrane roofs. Without ballasting or perforation of the membrane, the installation of photovoltaic panels is facilitated.

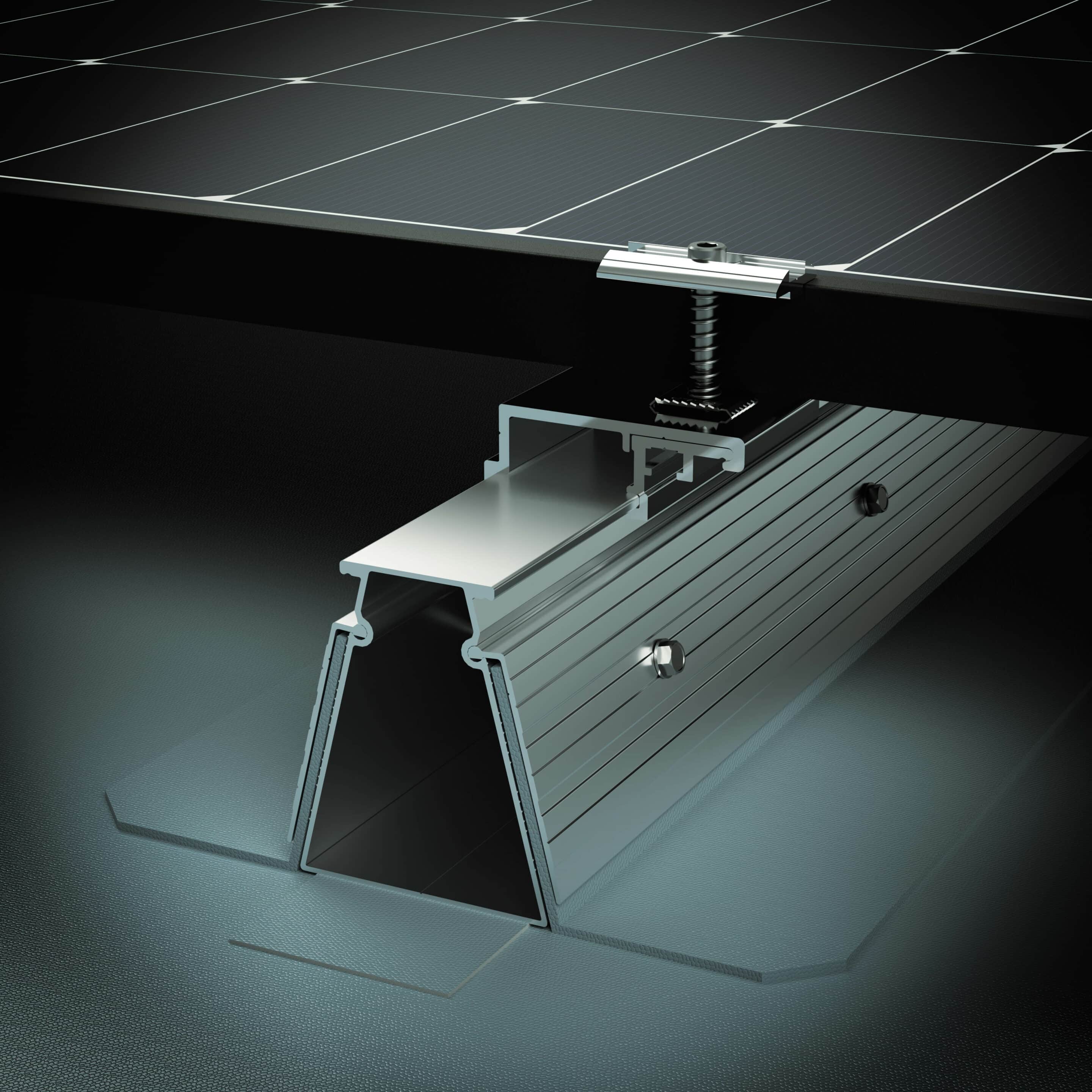

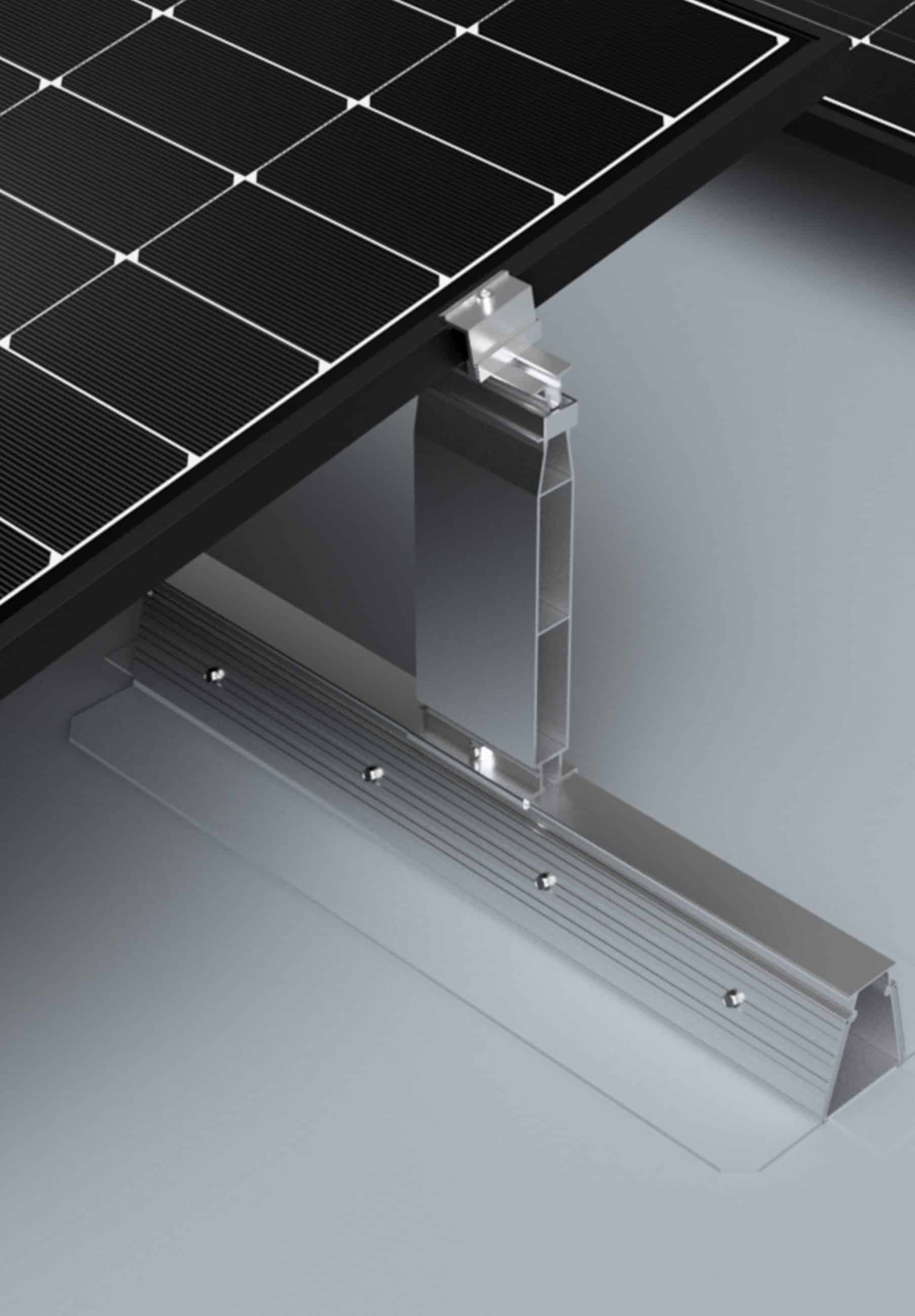

The use of 60 or 120 cm Roof-Solar Tilted PVC rails results in a linear load distribution (rather than point load), thus reducing the risk of puncturing.

Avis technique N°21/24-86

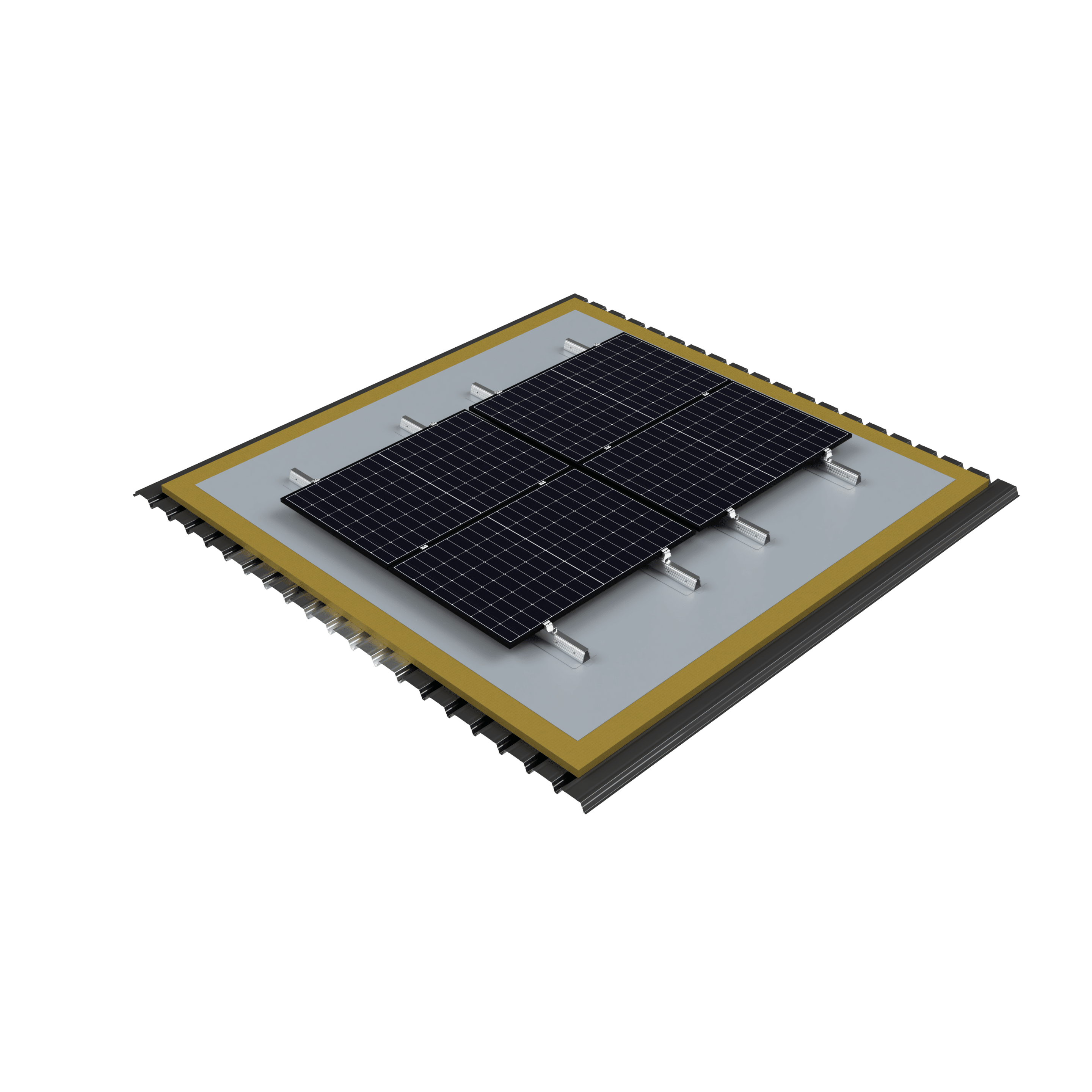

Portrait orientation

Documentation & Downloads

Request the manual

Contact us for a technical evaluation

Ask for a service

THE ADVANTAGES OF ROOF-SOLAR TILTED PVC

Advantages of the system

A technically evaluated mounting

Roof-Solar Tilted PVC photovoltaic mounting is a resistant solution that has undergone several tests to undergo a technical evaluation by a New Technology Survey (Enquête de Technique Nouvelle – ETN) by Alpes Contrôles: resistance to climatic loads, watertightness, condensation, corrosion resistance. All the results of these tests show the reliability of this mounting system.

A minimum load

Roof-Solar Tilted PVC allows solar panels to be installed on the roof in such a way that the added load on the building structure is as low as possible. The pre-assembled rails with the PVC retaining strips are thermally welded to the PVC synthetic membrane. Ballasting is therefore not required.

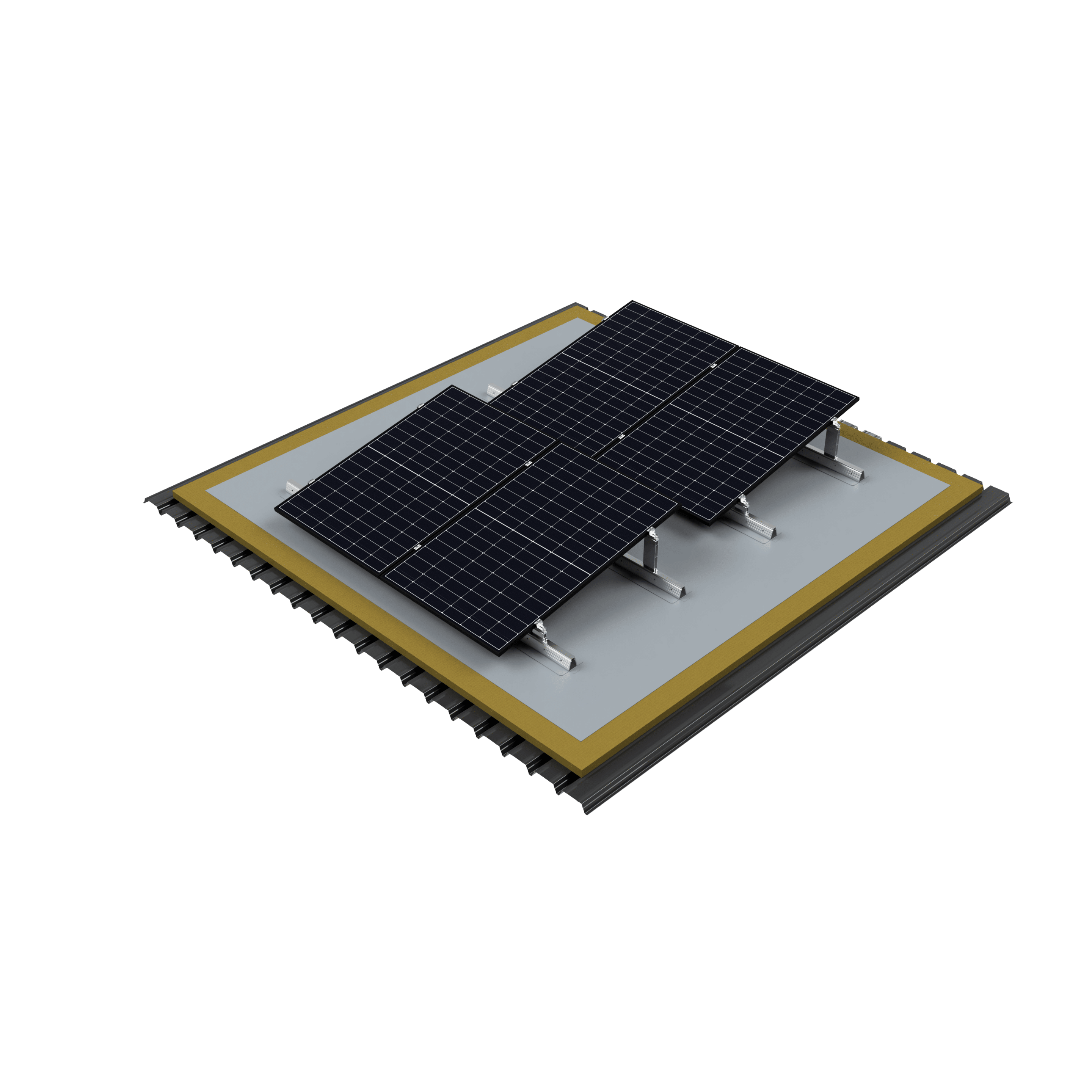

Tilting in the blink of an eye

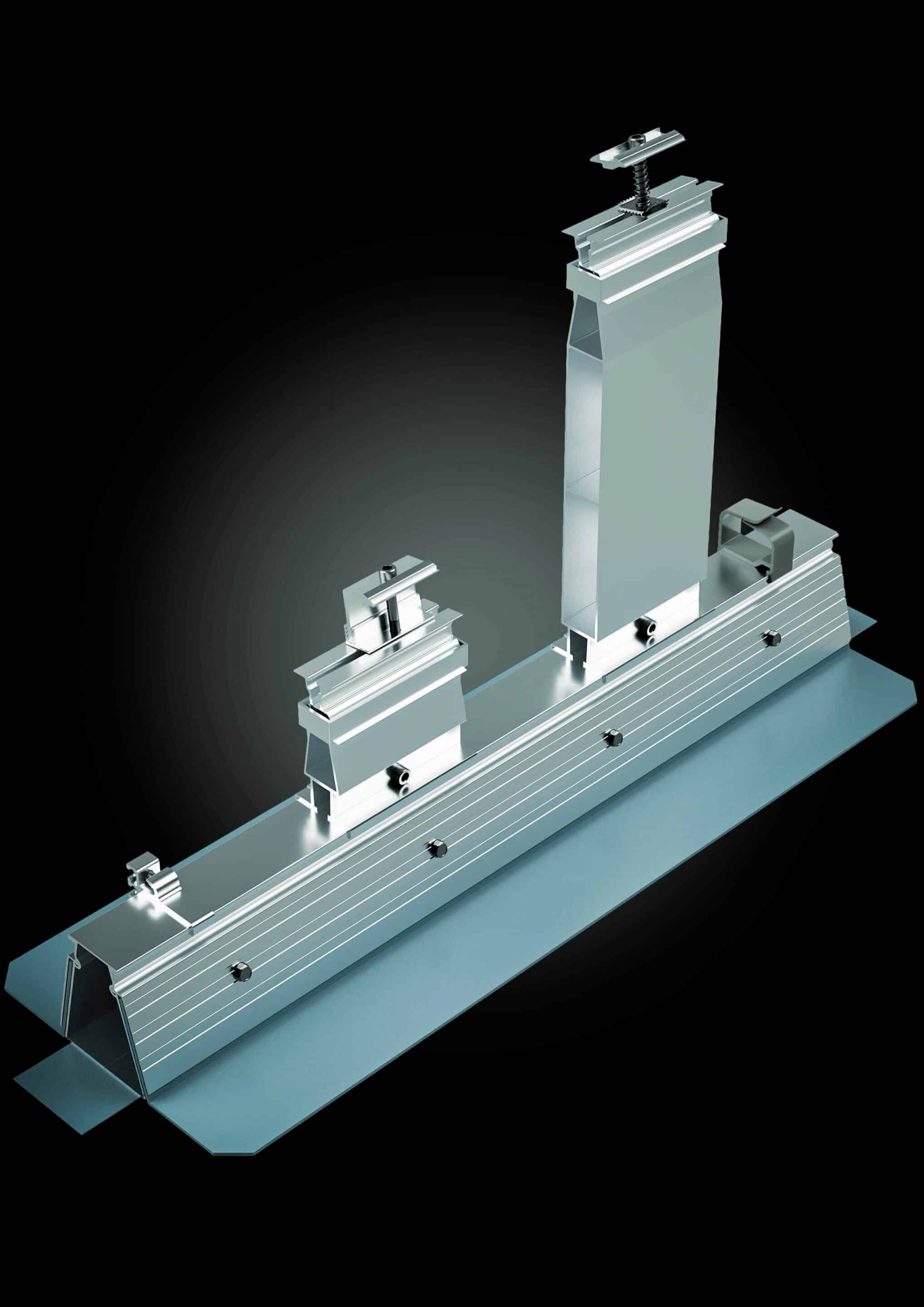

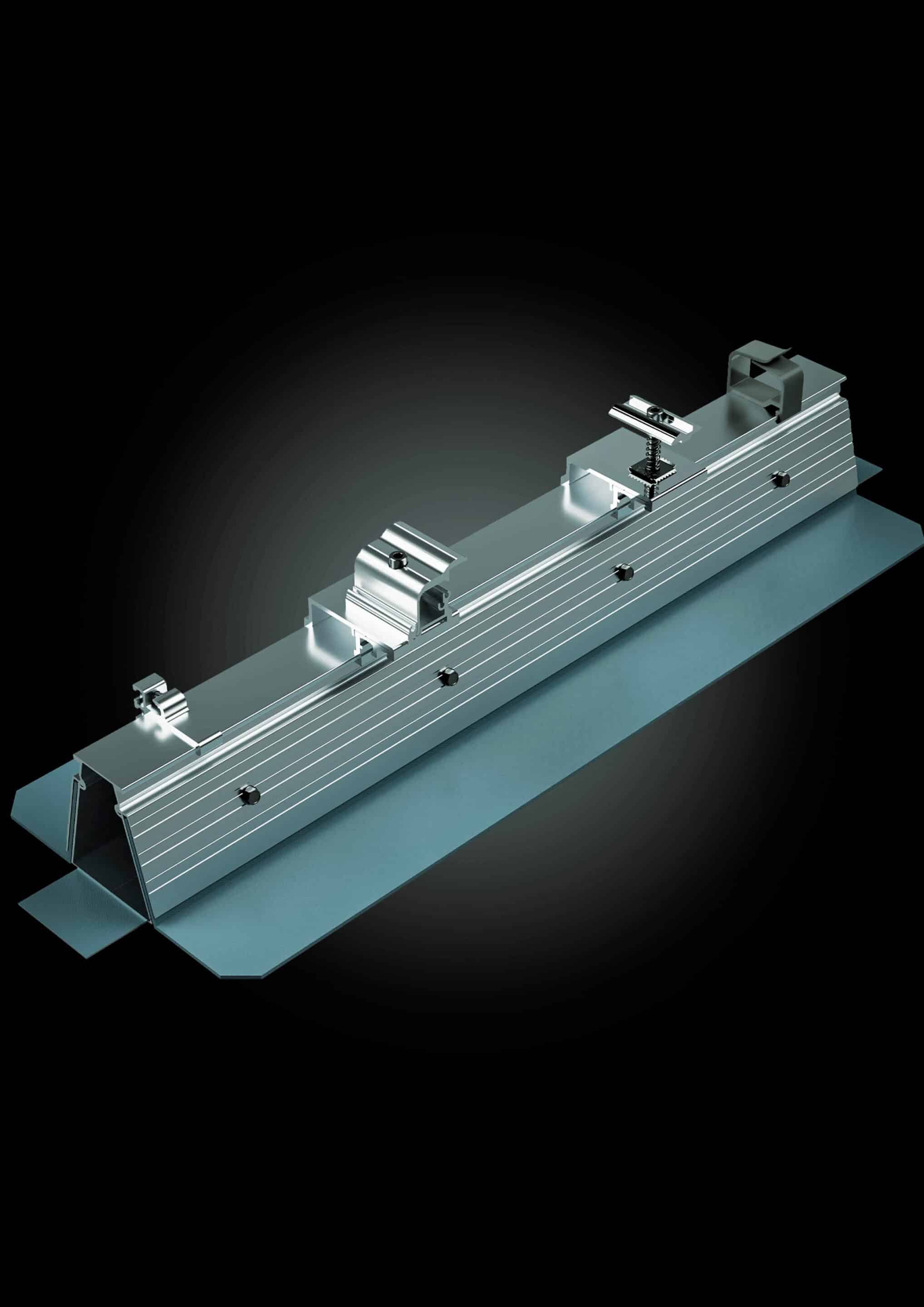

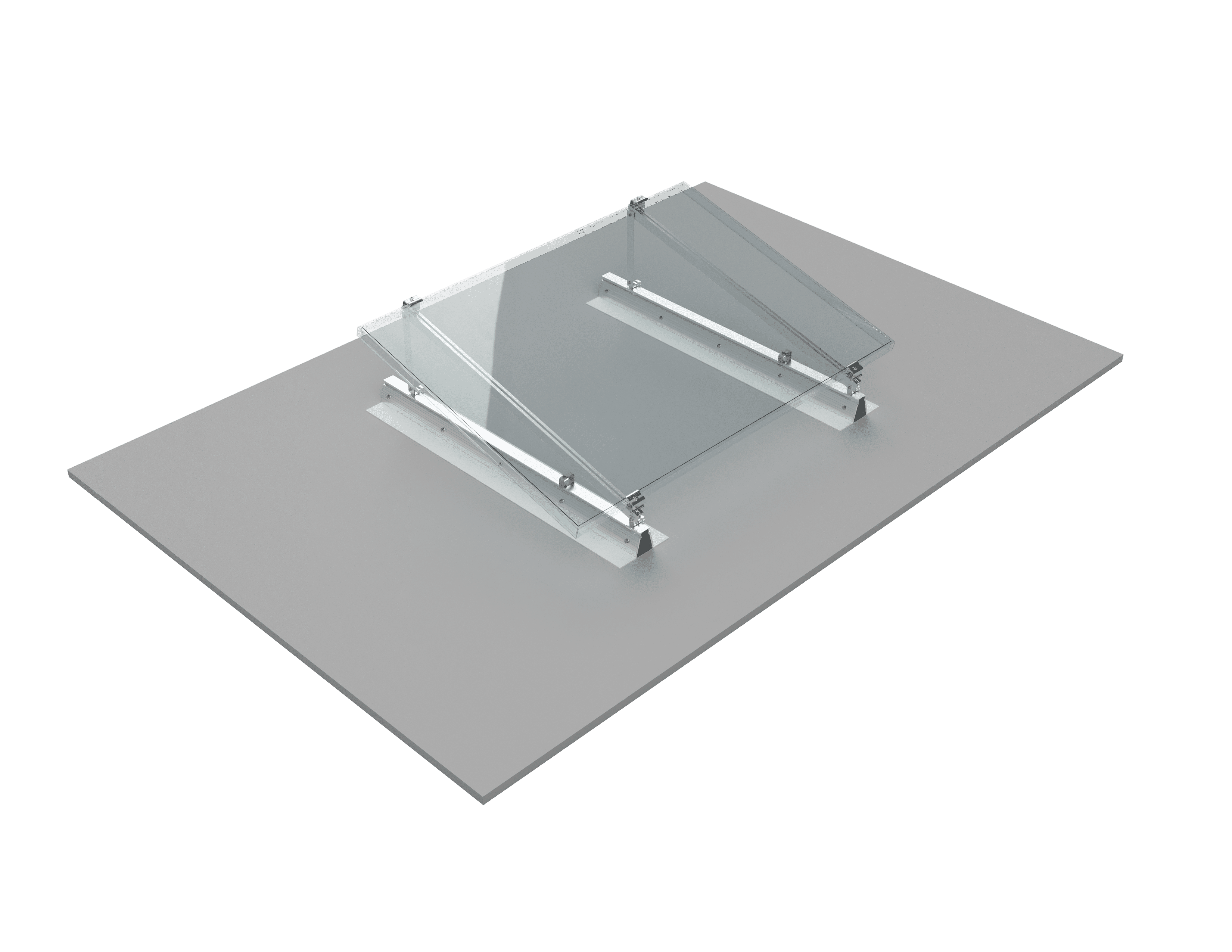

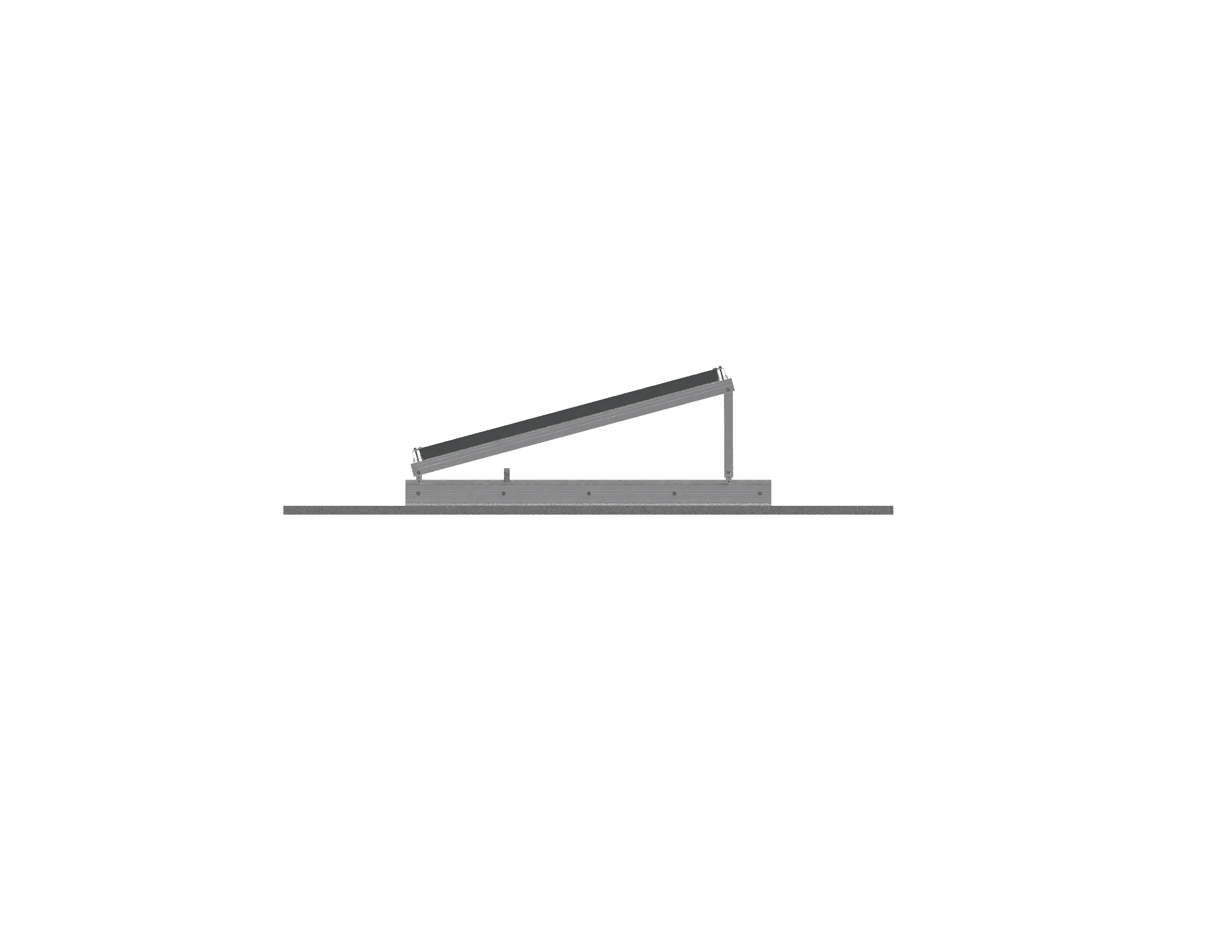

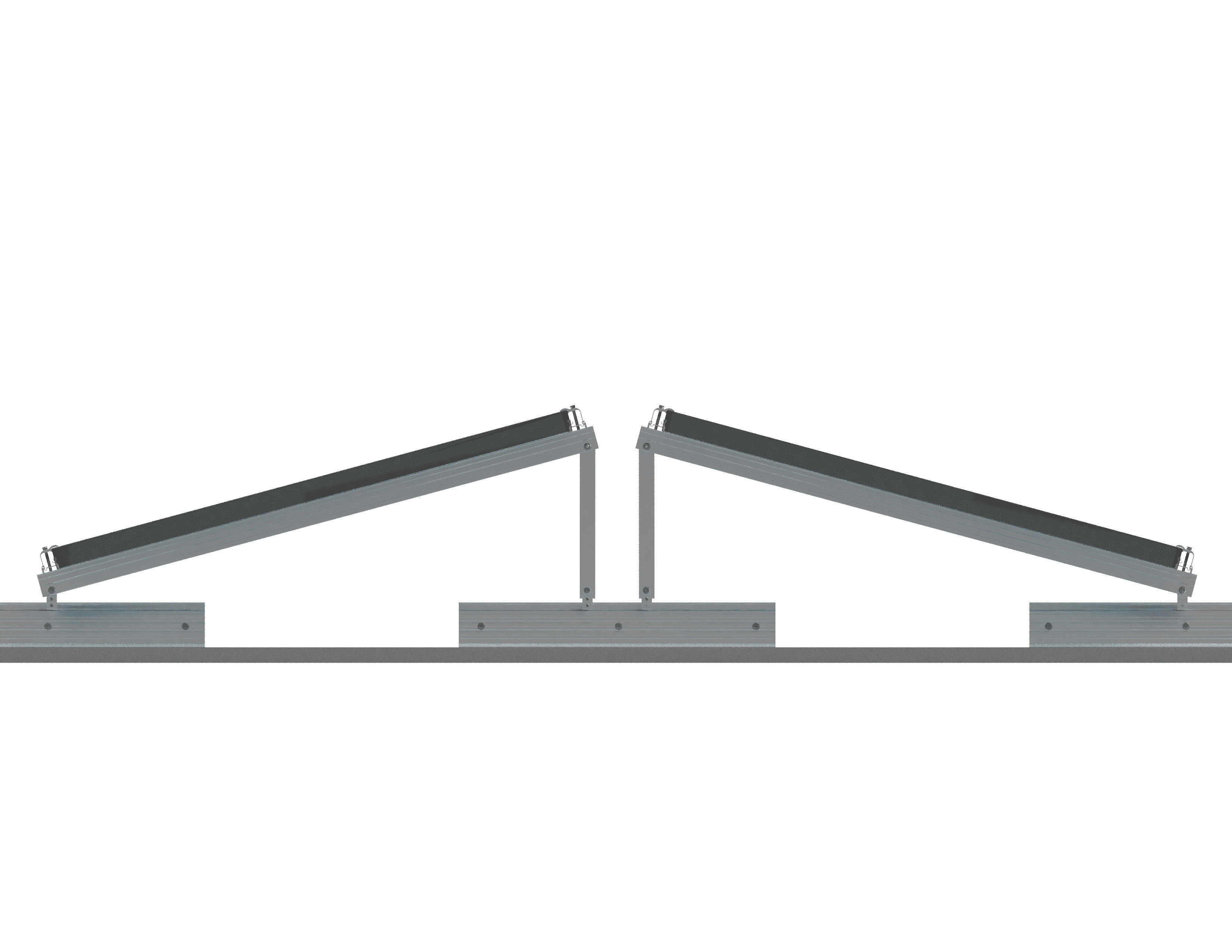

The tilting structure can be assembled prior to mounting on the roof. Light and easy to handle, it is attached to the rail in just a few seconds and gives you the option to tilt your solar panels at 10°. If you want a different tilting angle, this will require a custom-made structure.

A premium metal

The Roof-Solar Tilted PVC Inclined photovoltaic process uses 95% aluminium. This metal has many advantages including being light, strong, recyclable and highly resistant to corrosion.

Technical data

| USE | Enclosed building, new roof or total or partial renovation |

| TYPE OF ROOF | Concrete, ribbed steel sheets, wood. Insulation of compressibility class C. Synthetic waterproofing membrane. |

| MODULE POSITION | Portrait |

| MATERIALS | Aluminium, stainless steel and PVC |

| SYSTEM WEIGHT | 4.5 kg/m² |

| SYSTEM COMPONENTS | 0.6 or 1.2 m aluminium rail, retaining strip, flat bar (10°), “Y” rail, external clamp with aluminium/stainless steel finish, Module Grounding Connector (MGC), waterproofing patch, cable guide |

Benefit from training and first worksite assistance

Our experts share their tips and practical advice for quick and efficient installation

Discover all our products

SIMPLE TO IMPLEMENT

Dome Solar Roof-Solar PVC and Roof-Solar Tilted PVC photovoltaic systems have undergone a technical evaluation by a New Technology Survey (Enquête de Technique Nouvelle – ETN). Roof-Solar PVC also has a Broof (t3) fire resistance rating.

The membrane is installed by mechanical fastening, i.e. waterproofing sheets are fixed using suitable screws and plates.

INSTALLING SOLAR PANELS ON A PVC FLAT ROOF

Rails of Roof-Solar PVC and Roof-Solar Tilted PVC photovoltaic mountings are hot air welded (read more about the steps here) to the PVC membrane either manually or in a semi-automated way. Once External Clamps and then Universal Clamps have been clipped on, photovoltaic panels can be installed. Due to the heat-welding technique, no ballast needs to be added to the building’s roof, which reduces the weight. Moreover, membrane perforation is not required so there is no risk of water leaking in.